CNC G Codes Learn how to program CNC machines with GCode

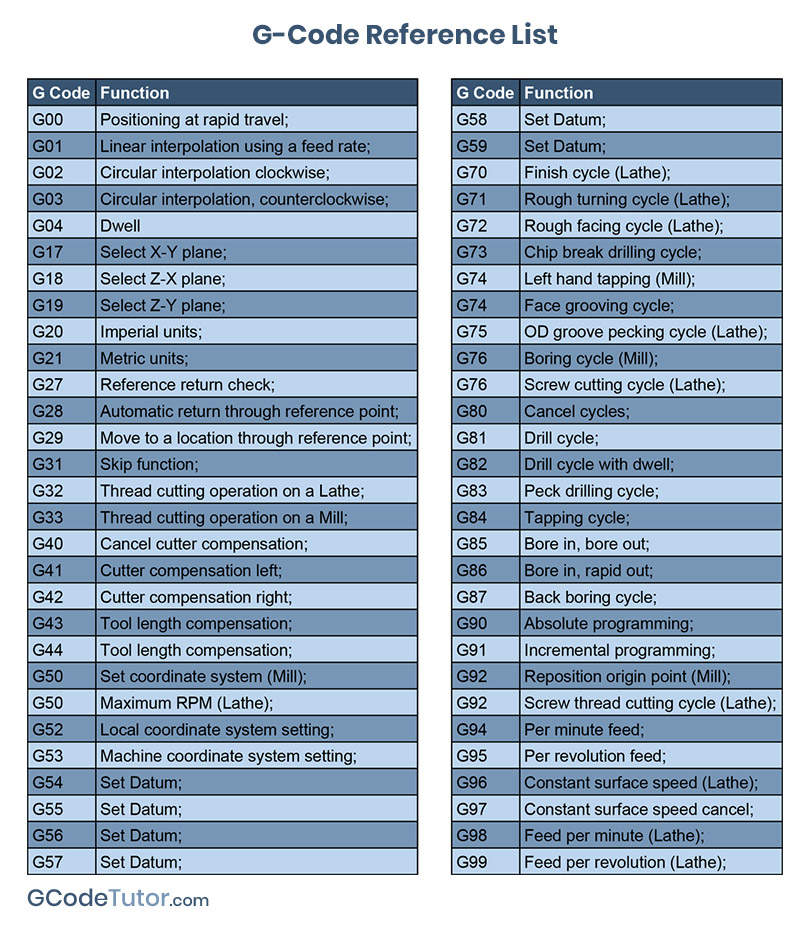

Complete G Code List. List of G-codes commonly found on Fanuc and similarly designed CNC controls. G00 Positioning (Rapid traverse) G01 Linear interpolation (Cutting feed) G02 Circular interpolation CW or helical interpolation CW. G03 Circular interpolation CCW or helical interpolation CCW. G04 Dwell. G10 Programmable data input.

CNC MILLING GCODE MCODE SOLO CAD DESIGNER

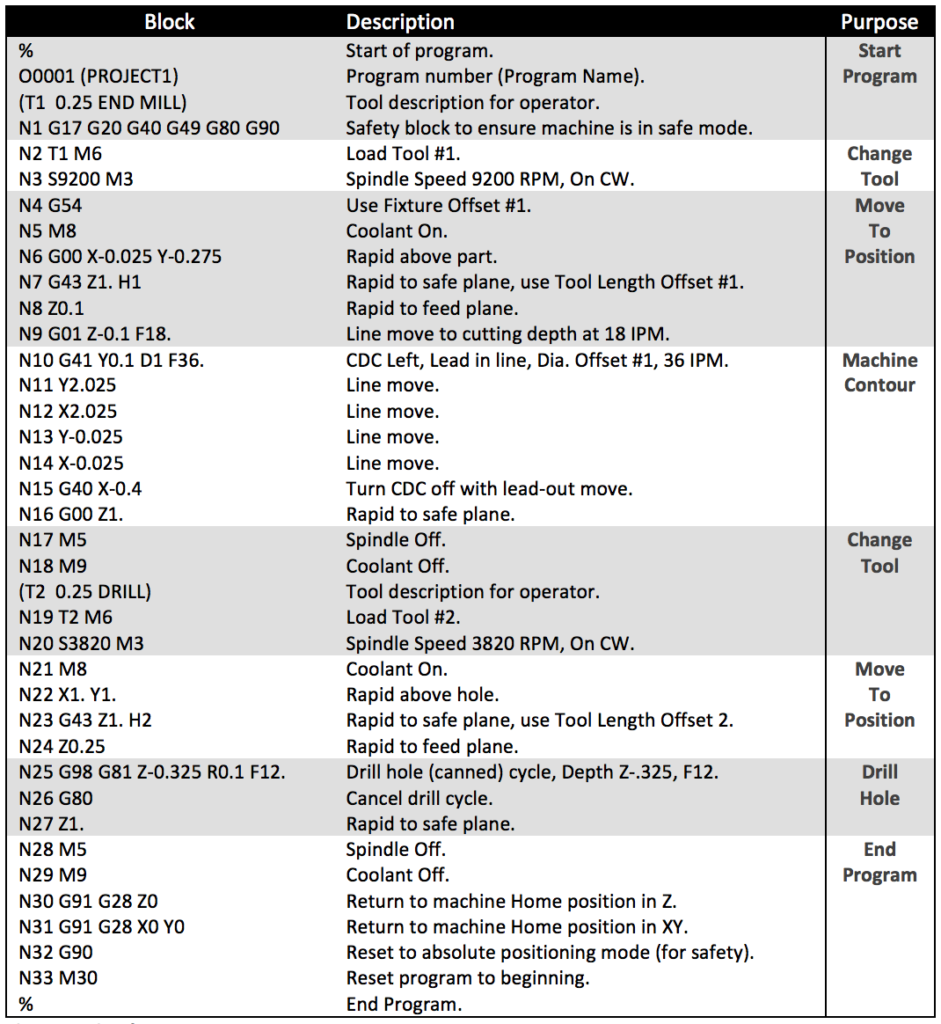

An example of a G-code section. There are different types of codes: 1/ Codes that start with G are preparation functions, which indicate a specific task to the machine as it is: "Make a hole". "Mill a line". "Move there". 2/ The codes that start with M are various machine commands. They are usually used to turn something on or off, such as a.

CNC Programming Courses Cnc lathe, Cnc programming, Code programming

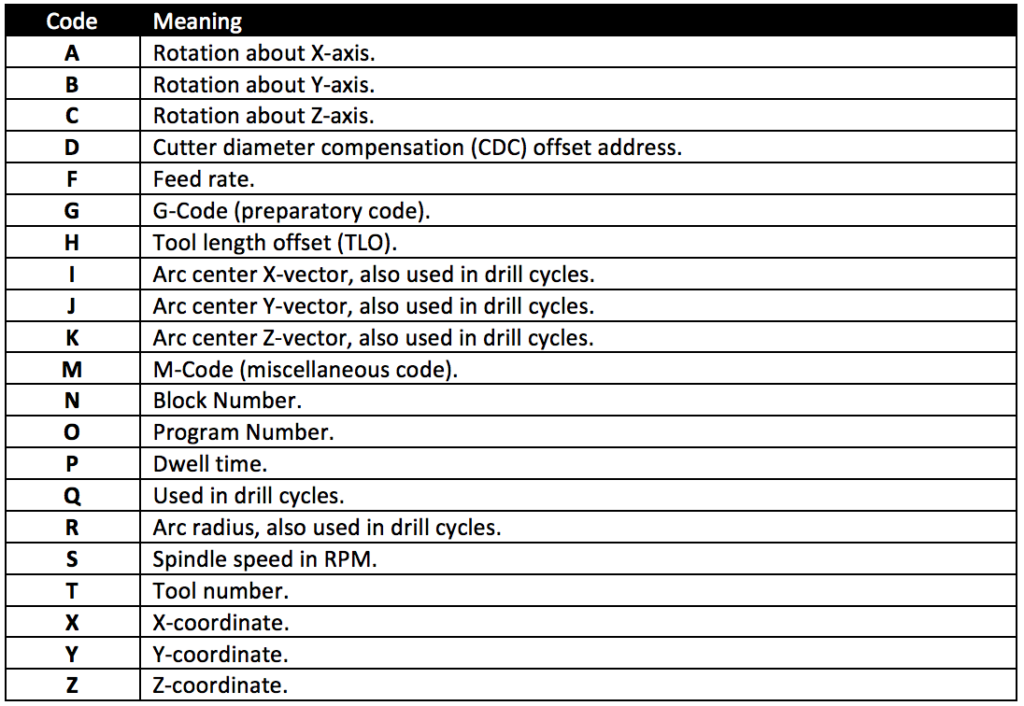

What Are G-Codes in CNC Programming? G code (also RS-274D) is the most popular CNC programming language. Most G code commands are in alphanumeric format and start with G which stands for geometry. They are responsible for the movements of CNC machines, telling the machine where to start, how to move, and when to stop when fabricating a part.

Common G and M Codes For CNC Machines PDF

G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. Each line in a block is labeled with the letter N and a number. These line numbers are generally only even numbers (N2, N4, N6.

CNC G & M Codes Explanation Turning & Milling CNC Programming Explained with example YouTube

T o control CNC machines we use commands called CNC G Codes. Although Different manufactures of the machine tool may adopt their own use for certain G Codes there is a core group that is common on every machine tool. These standards are used on CNC Lathes, Milling machines, routers and more recently by 3D printers (in a very basic form).

Well Set Out CNC Code (CNC Programming) CNC Training Centre

G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

CNC G Code Programming A CNC Mill Tutorial explaining G Codes YouTube

To create I & J codes you need to know the start point, end point and radius of the arc. The end point becomes the X and Y. The delta X and Y location relative to the radius centre point X and Y becomes the I and J values. You can also add a depth of cut value for Z as part of the block. Note that the Arc is assumed to run anticlockwise when.

Figure 7 from DESIGN AND IMPLEMENTATION OF FPGA BASED G CODE COMPATIBLE CNC LATHE CONTROLLER

G Codes make CNC Machines programmable, which gives them the flexible to make almost any part. What is the difference between G codes and M codes? G-Codes are about G eometry while M-Codes are about M achine functions. Do all CNC machines use G-code? Not all CNC machine use G-Code.

CNC Milling G+M Code List Metalworking Industrial Equipment

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

What are latest CNC part programming codes for beginners in 2021?

G-Code for CNC Programming (2022 Update) Marti Deans May 24, 2018 8 min read This post is also available in: Italiano (Italian) Deutsch (German) You know what they say about fundamentals: learn them first, and you'll remember them forever. The same holds true for CNC machine programming.

Cnc Programming

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.

Cnc Programming

How to mill a full circle, no problem below is the cnc program example G-code which shows how to program a full circle on a cnc milling machine. Often cnc… HAAS CNC Milling Machine Circular Interpolation Explanation with Example

cnc code for turning a profile YouTube

This video explains programming in G2/G3 mode with I and J for Haas mills, TSTC-Waco's Precision Machining Technology

MCodes are often on each CNC machine as the machine manufacture add thier own custom

How to Calculate I J K in CNC Programming (G Code) October 30, 2023 Leo Watts CNC Guides, Guides, Software, Software Guides Key Takeaways I J K method: Use the relative coordinates of the circle's center from the starting point to specify the circle. For example, G02 X8 Y0 I3 J4 K0. R method: Use the radius of the circle to specify the circle.

Cnc Programming

Mozaik CNC Version has everything a cabinet workshop needs to run its CNC Router. From design & cut lists to nesting & machine-ready G-Code it is a complete CNC Software

GCode for CNC Programming Fusion 360 Blog

There are a few dozen CNC programs, some have specific requirements, but in general, the line blocks are basically the same. I hope this will simplify the I,.