Cast Iron Block, कास्ट आयरन का ब्लॉक, कास्ट आयरन ब्लॉक, कच्चे लोहे का

Engine Block Materials: Aluminum vs. Cast Iron - A Comparative Analysis By Lambda Geeks When it comes to engine block materials, two popular choices are aluminum and cast iron. Both materials have their own set of advantages and disadvantages, making them suitable for different applications.

Rectangle Cast Iron Block at Rs 1400/piece Cast Iron Block in Howrah

Cast iron is a traditional and reliable material that is still commonly used for engine blocks, aluminum is a softer metal and can be machined more easily. For example, if an aluminum engine block gets cracked and has to go through a repairing procedure, you can use Epoxy or a TIG welder to fill the crack.

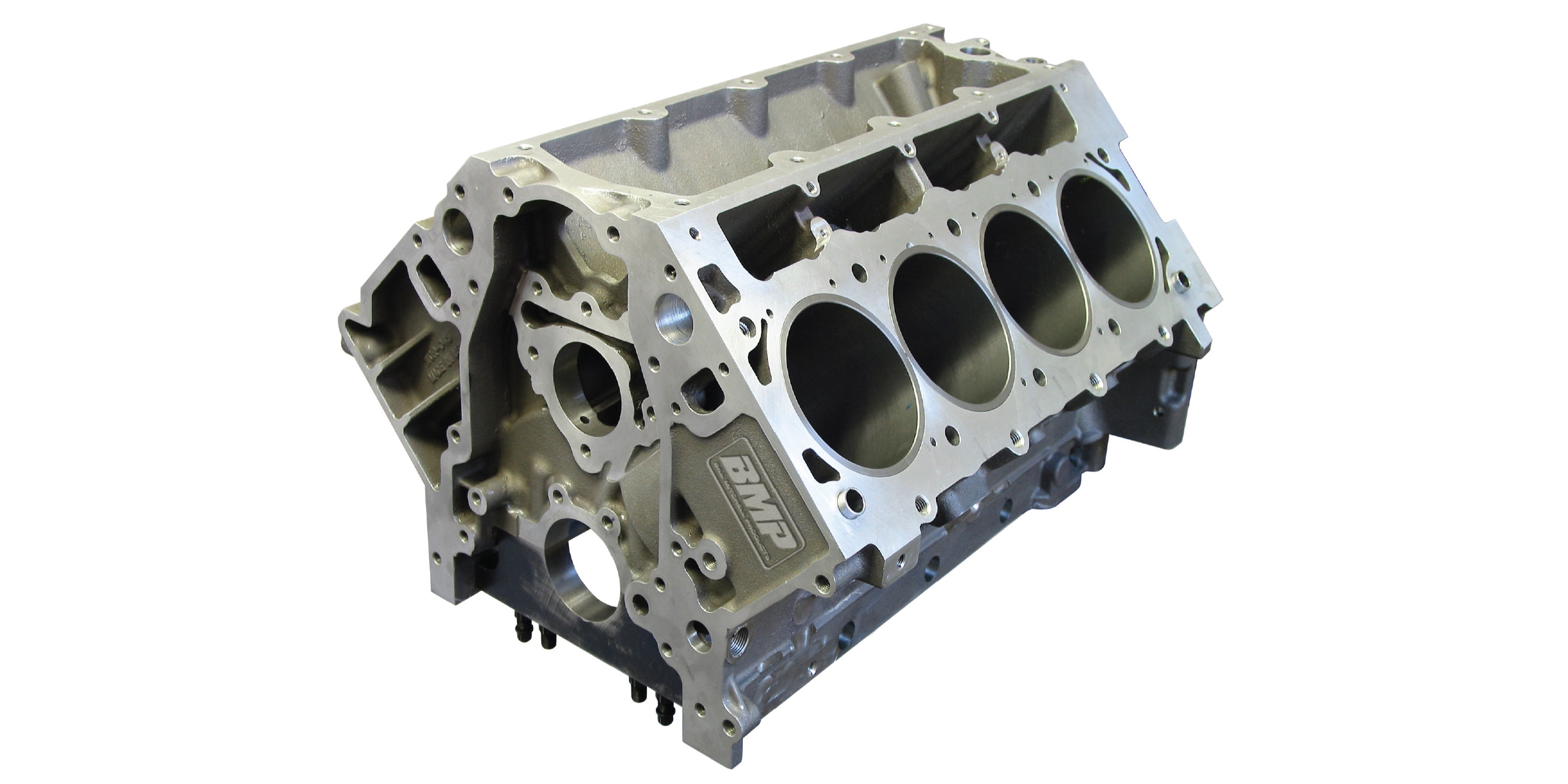

Brodix, Cast Iron Block, Chev BB, 4.500" Bore, 9.800" Deck

1 From what I can tell by reading, aluminium engine blocks are more thermally efficient than cast iron blocks - but it also seems that aluminium is more thermally conductive than iron. That seems counterintuitive to me. How come an engine that conducts more heat, is also more efficient?

Rectangular Cast Iron Block at Rs 80/kilogram कास्ट आयरन का ब्लॉक in

The weight-saving advantages of aluminum heads versus cast iron are obvious and widely accepted—especially in drag racing, where weight high up in the front of the car is especially undesirable.

Machining Aluminum Engine Blocks Engine Builder Magazine

The iron liners are cast in place when the block is cast and are not separable from the block. The pistons don't fit tightly enough for that to be a problem I don't think. A lot of engines in passenger vehicles are going to this setup of aluminum blocks and iron sleeves. The main reason is to save weight.

for sale cast iron block with v groove

There are also some key differences between cast iron and aluminum engine blocks. Cast Iron Versus Aluminum Engine Block: What Sets Them Apart? Cast iron engine block s are made from a metal alloy that is formed by melting iron, carbon, and silicon. The molten metal is then poured into a mold and allowed to cool and solidify.

Cast Iron Bearing Block at Rs 53/kilogram Pillow Block Bearing in

Cast aluminum is lighter and more corrosion-resistant than cast iron. Cast iron is stronger and better suited for high-heat applications. Both materials have their unique strengths and applications in various industries. Cast aluminum is commonly used in automotive parts and household items.

Cast Iron vs. Stainless Steel vs. Aluminum Cookware Which is Better

#1 · Jan 26, 2012 I wanna do a 402 stroker kit here pretty soon and i was wonder what would you guys recommend. staying with my ls2 aluminum block or getting a iron block. i hear you can go a little bigger on the stroker kit with a iron block. im also doing 150 shot .

Cast Iron Engine Block vs Aluminum Which is Better? Motorsrun

Pros Iron blocks are cheaper than aluminum blocks. On average, a pound of aluminum costs $1 while a pound of iron only costs 25 cents. That said, it's easy to accept that the use of iron will reduce production costs, making it more appealing. The reason why iron is the standard material is due to its durability.

Cast Iron Block Manufacturers & Suppliers, Dealers

Make The Case: Iron vs. Aluminum Engine Blocks Image For many racers, choosing which engine block material to invest in often comes down to two factors: cost and strength.

Aluminum Vs. Cast Iron Engine Blocks It Still Runs

36 aFacelessBlankName • 1 yr. ago the answer is "maybe. Depends." I love the honesty of that. Not everything is black and white. Saturnino_97 • 1 yr. ago Doesn't the Al block warp easier under heat though? MilesBeforeSmiles • 1 yr. ago Yes, but because it dissipates heat better you are less likely to burn a piston or any of the other internals.

Pros And Cons Of Iron Vs Aluminum Engine Blocks

.jpg)

One of the key differences between cast iron and aluminum engine blocks is their weight. Cast iron engine blocks are heavier than aluminum engine blocks, but they also offer greater strength and durability. Cast iron engine blocks can withstand higher internal pressures and temperatures, making them ideal for use in high-performance engines.

Aluminum Vs. Cast Iron Engine Blocks It Still Runs

319 Alloy. Its composition is: 5.5% to 6.5% silicon, 3% to 4% copper, nickel, titanium, manganese, iron, zinc, and magnesium in small quantities (0.1%-1%), and the rest - aluminum. It receives T5 treatment to harden and strengthen the metal.

Make The Case Iron vs. Aluminum Engine BlocksPerformance Racing Industry

Jul 27, 2017. Aluminum engine blocks have been around for many years for both stock and performance applications. Aluminum has a number of advantages over cast iron, the most obvious one being weight. An aftermarket aluminum V8 block will typically weigh about 80 to 100 lbs. less than a comparable factory cast iron block of similar displacement.

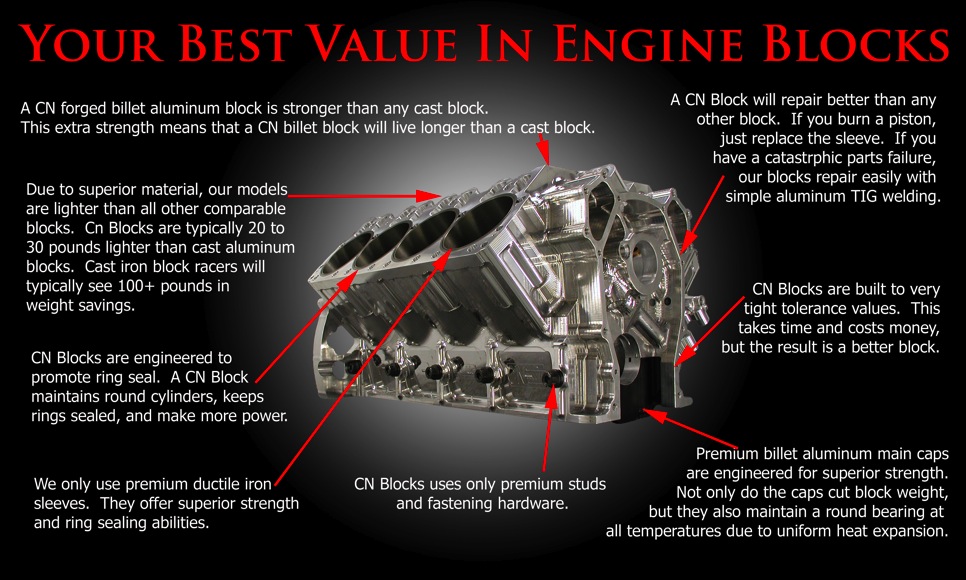

CN Blocks Why Billet?

What is up engine heads, welcome to another episode of engine boot camp, and today we're talking about the backbone of every engine, the engine block! D4A me.

Aluminum Vs. Cast Iron Engine Blocks It Still Runs

Pros Strength: Cast iron blocks are typically stronger than aluminum engine blocks, and they can stand up to higher internal pressures. Power: On balance, iron engine blocks are going to produce more horsepower than aluminum engine blocks.