Ferrock une alternative au béton plus solide, plus flexible et plus verte ? Build Green

Ferrock is a sustainable, strong, durable, and cost-effective alternative to cement and concrete. It is a new material that is made from waste products like steel dust from the steel manufacturing industry, and it can be an excellent replacement for conventional building materials like concrete, which has a substantial carbon footprint.

Ferrock, the cement that captures carbon from the air, comes to market The Optimist Daily

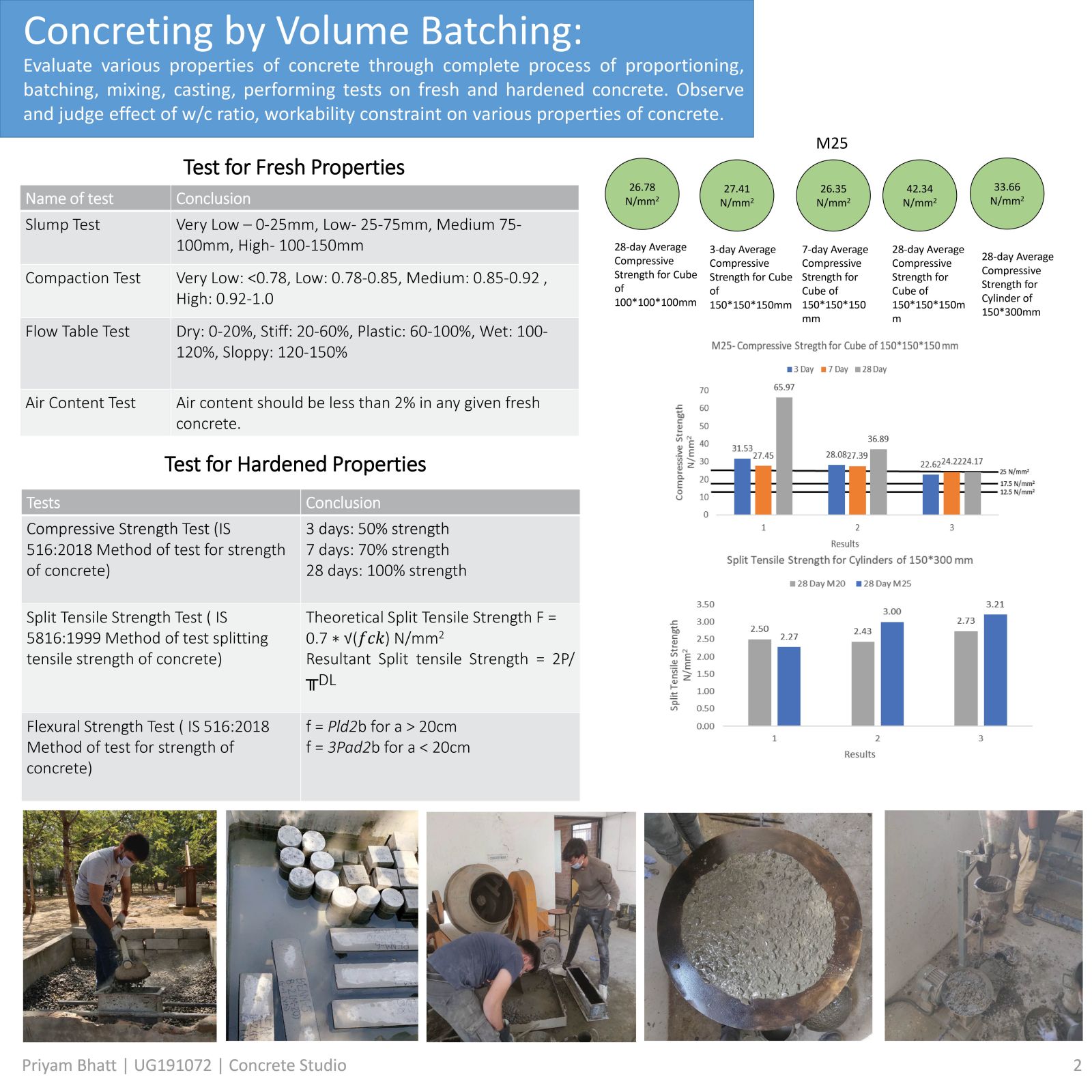

A target compressive strength of C32/40 or M40 concrete was selected for this study to achieve and compare results with the control mix (0% ferrock) and conventional ferrock during the.

Ferrock es un nuevo material que utiliza materiales reciclados, incluido el polvo de acero de la

An In-Depth Look At Ferrock And How It Compares To Concrete . Concrete is one of the most common construction materials in the U.S., with over 68 million metric tons of the material produced in 2004. It's considered the standard building material for a wide range of construction projects, from ordinary residential homes to towering skyscrapers and massive hydroelectric dams.

CarbonNegative Replacement For Cement Traps CO2 During Manufacturing

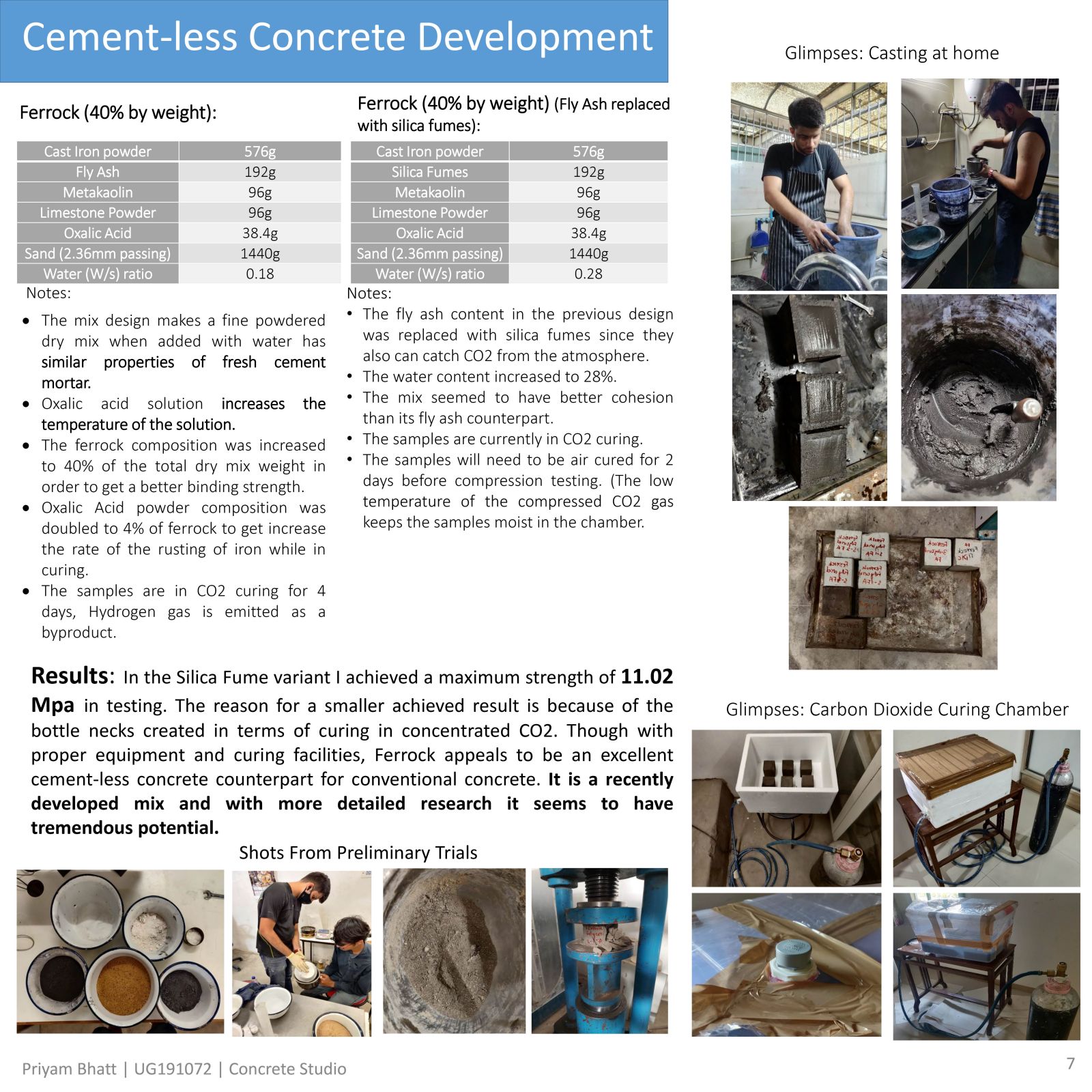

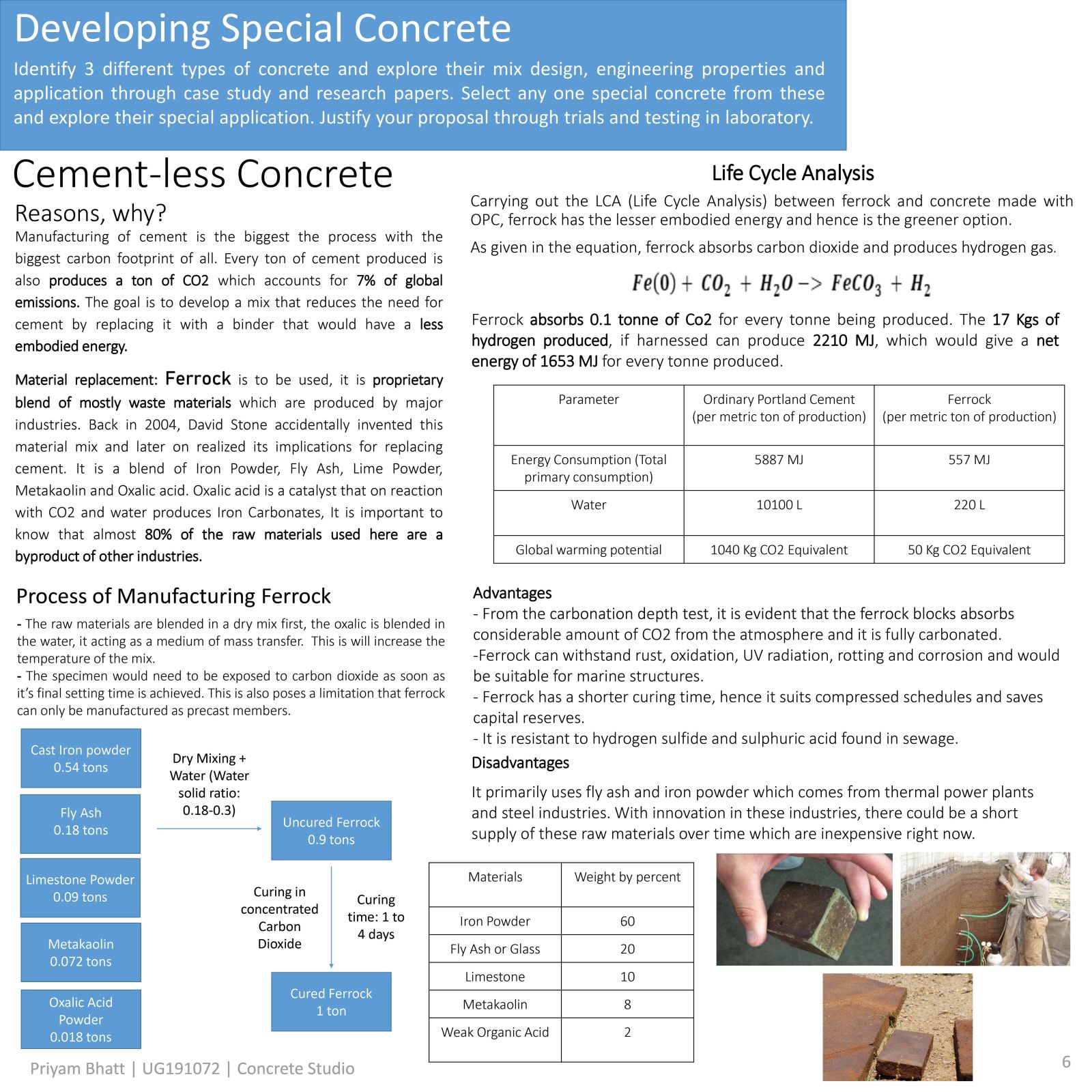

CT2015. Ferrock | Cement-less Eco-Friendly Concrete. The journey goes through understanding basic properties for conventional concrete and then later on developing a specialized concrete. My goal was to develop cement-less concrete, removing the necessity to use cement reduces the embodied energy of the product developed contributing towards an.

What is Ferrock in Construction? The Constructor

In the case of compressive strength, Ferrock shows typical strengths in the range of 5,000 to 7,500 psi, and even as high as 10,000 psi. These values are above the 28-day cured OPC standard values for commercial use (4786 psi for OPC-33 MPa, 6236 psi for OPC-43 MPa and 7687 psi for OPC-53 MPa).

Un sustituto del cemento El ferrock

Stronger Than Concrete. Ferrock has been proven to be five times stronger than traditional concrete. It also has a much higher compression strength and much more flexibility as well. CO2 Negative. Ferrock is CO2 negative, which means that instead of emitting CO2 as it dries (like concrete), Ferrock absorbs and binds CO2 to itself.

Ferrock poderia substituir o concreto? Arquitecasa

Abstract. Concrete, the second most used entity after water around the globe which accounts for 8 to 10% of total CO 2 emissions is mainly due to cement. This proposes to evaluate the ability of Ferrock to be used as one of the best possible substitute for cement in concrete. It is an iron based binding compound which utilises variety of waste.

Ferrock Cementless EcoFriendly Concrete CEPT Portfolio

Ferrock as an alternative to cement. Ferrock is five times stronger than the typical Portland cement (powdery building material made of chalk, concrete, mortar and clay) and can withstand more compression caused by seismic activity. The material is also relatively chemically inactive, which makes it a better option for marine-based constructions.

ferrock cement

Ferrock is made by combining steel dust waste with silica. A chemical reaction between the iron in the dust and the carbon dioxide in the air causes the mixture to turn into iron carbonate. Once this is mixed with water and exposed to carbon dioxide, it hardens into a solid form, similar to concrete. In this article, we will discuss the process.

Evaluation of FerrockA Greener Substitute To Cement PDF Concrete Cement

Ferrock concrete is also far better for the environment than Ordinary Portland cement, instead of emitting large amounts of CO 2 as it dries, Ferrock actually absorbs and binds it. This results in a carbon negative process that actually helps trap greenhouse gases (Geiger 2017). Ferrock also uses significantly less energy, water, and GWP as

Ferrock_ a Stronger, Greener Alternative to Concrete Concrete Cement

Abstract. Concrete, the second most used entity after water around the globe which accounts for 8 to 10% of total CO 2 emissions is mainly due to cement. This proposes to evaluate the ability of Ferrock to be used as one of the best possible substitute for cement in concrete. It is an iron based binding compound which utilises variety of waste.

Ferrock a carbon dioxide sponge that’s harder than concrete Science! Concrete

The strength of ferrock is five times the concrete strength. It is commonly between 34.5 Mpa to 48 Mpa, and some ferrock tests reached 69 Mpa. Ferrock has greater flexibility than conventional concrete. That is why it sustains movement and pressure without cracking. It bears more compression load caused by seismic forces when compared with.

How Is Ferrock Made? BuilderSpace

The invention, called Ferrock, uses the waste steel dust from industrial processes to create a cement-like material that is sustainable, strong and environmentally superior to conventional cement. Cement is the binder in concrete, which also includes aggregate such as sand and gravel.

Ferrock Cementless EcoFriendly Concrete CEPT Portfolio

Ferrock Concrete. "David Stone is the brains behind a new patented concrete technology known as Ferrock, based on iron carbonate and incorporating largely recycled materials to produce (around 95%)! It's showing promising signs as an alternative to concrete and a far greener building material. The name Ferrock is a reflection of its.

Ferrock Cementless EcoFriendly Concrete CEPT Portfolio

The flexural strengths of conventional and Ferrock concrete are shown in Fig. 3, which shows that the flexural strength of Ferrock concrete is 1.24 times that of conventional concrete after 7 days and 1.17 times that of conventional concrete after 28 days. This definite increase is attributed to the presence of iron components in the concrete.

Denne sementen spiser CO2 Tu.no

Ferrock's ability to actively absorb carbon dioxide, coupled with its reduced energy consumption during production, positions it as a greener alternative to traditional concrete. The recycled steel dust component further contributes to its eco-friendly credentials. Ferrock vs. Other Sustainable Materials.